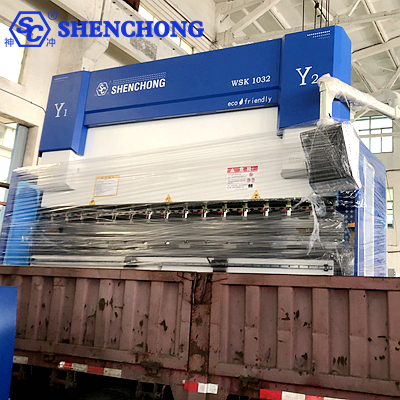

This is a WSK CNC Press Brake with a 100-ton capacity and a 3200mm bending length. The machine also has a 4+1 axis configuration and is controlled by the EL15T CNC system. This type of press brake is typically used for precision bending of metal sheets and plates in various industries, like automotive, aerospace, or heavy manufacturing.

100-ton capacity means it can apply a bending force of up to 100 tons.

3200mm bending length indicates the maximum sheet length it can handle.

4+1 axes usually means it has 4 linear axes (X, Y, Z, and R for movement) plus 1 additional axis (like an angle or crowning adjustment).

SC EL15T CNC system is likely a specific control system used to automate and fine-tune the machine's bending operations.

WSK CNC Press Brakes are designed for high-precision bending, ensuring that each bend is made to the exact specifications with minimal variation. This is achieved through advanced servo motors, high-quality components, and the precision control of the EL15T system.

Repeatability: Press brakes from WSK are known for their consistent output, making them ideal for batch production runs where parts must be identical.

Accuracy: With features like crowning systems, high-end hydraulic components, and precise back gauge control, the WSK CNC press brake can bend parts with tight tolerances.

WSK CNC Press Brakes are often designed with energy efficiency in mind. Hydraulic and servo-electric versions of press brakes are available, offering different levels of energy consumption, which can help reduce operational costs, especially in high-production environments.

The WSK CNC Press Brake with 100 tons of force and 3200mm bending capacity is an excellent solution for industries requiring precision, high throughput, and versatility in metal bending. Coupled with the EL15T CNC system, this machine offers automated control, safety, and ease of use while maintaining high accuracy across various sheet metal bending applications.