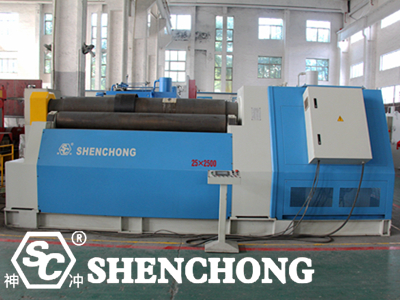

W12 CNC four-roller plate rolling machine is a commonly used metal sheet cold bending equipment, which is widely used in the curling processing of metal sheets and can bend metal sheets into round or other curved shapes. It is usually used to manufacture oil drums, pipes, metal containers, cylinders and other products.

- Wide application range: It can process metal plates of various thicknesses and widths. Common metal materials include steel plates, stainless steel plates, aluminum plates, etc.

- Easy operation: The equipment is reasonably designed and easy to operate, suitable for mass production and small batch customization.

- Strong adjustability: The lifting and lowering of the upper roller can adjust the bending degree of the plate, thereby affecting the curling diameter.

- High precision: The equipment can achieve higher processing accuracy, and the quality of the finished product after curling is better.

- Upper roller: mainly used to apply pressure and drive the plate to rotate.

- Lower roller: used to support the plate and form a bending moment with the upper roller.

- Side roller: two side rollers can move independently, used to provide lateral support and precise positioning of the plate to ensure processing accuracy.

- The plate enters W12 CNC four-roller plate rolling machine through the feeding system.

- The CNC system controls the position of the upper and lower rollers and side rollers according to the input processing parameters.

- The upper roller applies pressure, the side roller provides support, and the bending and forming of the plate are completed through the rotation and relative movement of the rollers.

The final product is automatically output, reducing manual intervention.

W12 CNC four-roller plate rolling machine is a high-precision and high-efficiency metal plate processing equipment, which is an advanced type of plate rolling machine. Compared with the traditional three-roller plate rolling machine, the combination of four-roller structure and CNC technology makes it have a higher level of automation and a wider range of applications. If you need to know the specific model, technical parameters or purchase suggestions, please provide more details and we can give you further answers!