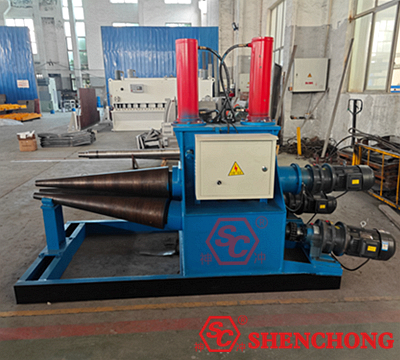

This equipment is a Hydraulic Symmetrical Cone 3-Roll Plate Bending Machine W12ZT-6X1000, used to bend metal plates of a certain thickness into tapered parts at room temperature.

Its working principle is rotary bending deformation. The hydraulic symmetrical cone three roller plate rolling machine is an essential equipment in the manufacturing industry of machinery and equipment such as petroleum, chemical, cement, shipbuilding, boilers, aviation, water conservancy, and power transmission and transformation towers.

- Machine model and specifications: W12ZT-6X1000 hydraulic symmetrical cone three roll rolling machine

- Maximum thickness of rolling plate: 6mm

- Working surface length of work roll: 1000mm

- Yield limit of rolling plate: 235Mpa

- Upper roller diameter: 260mm (tapered maximum end)

- Lower roller diameter: 260mm (tapered maximum end)

- Roll shaft small mouth size: 50mm

- Work roll rotation drive method: three roll mechanical drive

This equipment mainly consists of integral base, fixed side frame, work roller, main transmission device, upper roller lifting device, hydraulic pump station, electric control system and other components. The entire machine has a compact structure, reliable use, and convenient maintenance. The up and down movement of the upper roller is carried out by hydraulic devices. Therefore, the operation is convenient and the control is accurate.

The three working rollers of this machine are all active. After being decelerated by the main motor through a reducer, the output causes the three rollers to rotate. The three tangent points that come into contact with the metal plate through three rollers form an arc, causing the plate to bend. Adjusting the amount of pressing on the upper roller can achieve the required curvature radius of the curved or conical workpiece. The straight edge section of the final product is ≤ 2.5 times the plate thickness (multi pass forming).

The overall base of the conical circular rolling machine is made by welding and stress relieving the section steel and steel plate as a whole. Both strength and rigidity are good. Easy to install and use. Especially suitable for production requirements with strong liquidity.

The requirements for the foundation are relatively low, and the relocation work is convenient. Beneficial to workers' operation. Simultaneously install the machine frame, reducer, motor, etc. on it to form a whole.

The work roll is an important component of the rolling machine and is a refined forging. The material is 45 steel. The two end journals of the three working rolls adopt a new type of ultra wide large double row self-aligning roller series rolling bearing. Long service life. Save power consumption. Improve the efficiency of the main transmission. Reduce the power of the main transmission. Due to the use of self-aligning roller bearings, it is beneficial for the upper roller to tilt.

The main transmission system consists of a main motor (non variable frequency, non adjustable speed) and a reducer. It can rotate forward and reverse, providing power for sheet metal rolling.

When rolling conical workpieces, the tilt of the upper roller is controlled by the two oil cylinders of the upper roller.

The independent hydraulic pump station is composed of oil pump motor, hydraulic valve group, pipeline auxiliary components, etc. A high-pressure gear pump is driven by an oil pump motor to output pressure oil through an internal toothed elastic coupling. To ensure the cleanliness of the oil, an oil filter is installed at the oil pump port. The pressure oil from the oil pump first enters the pressure regulating system, sets the pressure, and then passes through the channel block, leading to the oil cylinder through a three-position four-way directional valve.

The production of hydraulic pump station system strictly follows national and industry standards, and the layout is reasonable. Fully consider efficiency and energy conservation, reduce waste, and reduce heat sources.

System independence. Appropriate connection points should use professional sealant to prevent leakage. Convenient maintenance and repair. The hydraulic pumps and valves are all selected from famous brand series, and the oil cylinders are customized and produced by professional hydraulic cylinder factories as supporting products. The pipeline layout is simple and has minimal leakage. Easy maintenance and debugging.

The electric control system consists of an electric control cabinet and a handheld control box. The control electrical appliances of hydraulic symmetrical cone 3-roll plate bending machine are all installed in the distribution cabinet. Easy to operate.

The main circuit adopts three-phase 380V/50Hz AC power. A motor drives a set of hydraulic pump stations with short-circuit and overheating protection. The structural layout is reasonable and necessary safety protection measures are in place.