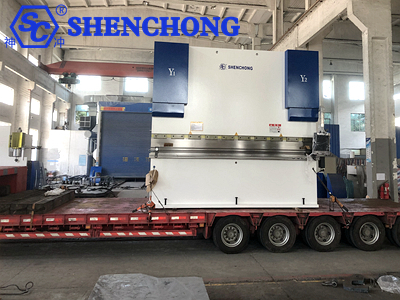

- WEK electro-hydraulic series

- 400Ton 4000mm(13ft)

- CNC system ESA S630

- 3+1axis

The frame of the hydraulic cnc press brake machine is made of all-steel plates that are welded and tempered to eliminate stress through vibration. Good stability.

The bending machine is sandblasted to remove rust and sprayed with anti-rust paint.

The frame is clamped and formed in one step by an imported CNC three-dimensional machining center to ensure the parallelism and verticality of each installation surface.

- Upward bending design. Low noise. Stable and reliable working status.

- We can program Y1 and Y2 axes independently and work under offset load.

- There is a pressure holding time at the bottom dead center. Programmable. Ensure the accuracy of different parts.

- Slow recovery control function. The operator has better control over the workpiece.

- SC electro-hydraulic cnc press brake machines all use split oil tanks.

- There is an independent shock-proof buffer layer. The mute effect is better.

- The quality of the oil cylinder is stable and easy to maintain. Made of 45# steel forged and tempered. Precision boring and extrusion of inner hole.

- The piston rod is forged and tempered from No. 45 steel. Chrome plated outer circle.

- Adopt electro-hydraulic servo synchronous control system. The hydraulic system has overload overflow safety protection. The oil level is clearly and intuitively displayed. The seals in the oil cylinder are all imported. Good quality and strong performance.

- Working continuously under rated load, the hydraulic system ensures no leakage and continuous stable processing with high precision.

- Suitable for producing multi-pass bending and high-precision workpieces.

- The X-axis of the backgauge is driven by ball screws and linear guide rails. Digital AC servo motor drive. The backgauge has a retreat control function.

- High-definition 10-inch TFT color touch screen

- Built-in PLC

- 2D graphics programming

- Expansion length calculation

- Graphic upper and lower molds, supporting polygonal molds, telescopic molds, arc molds, gooseneck molds and other molds

- Automatic and manual optimization of graphics programming

- Support simulated bending

- Supports graphic or numerical arc bending

- Supports dual-machine linkage function, no need to purchase additional synchronization card

- Form-filling programming mode with real-time automatic checking, automatic calculation of bending and compensation force

- Manual bending option: single-step bending, no program interruption

- All programs, molds and parameters can be saved in the local memory or USB flash drive

- These data can be uploaded to other CNC or PC via USB flash drive

- User-defined alarm information function

- Provides programming functions for controlling axes and other auxiliary functions, and can drive hydraulic axes with proportional valves or servo valves.

- AC/DC servo drives, AC motors with or without frequency converter, to drive the most common current buses

- Interface connection for front support, thickness detection, angle measuring instrument, and manipulator

- Safe PLC communication function (PILZ, LAZER SAFE)

- Remote assistance function

- High-performance dual-machine linkage function, no need to add additional signal connections between two press brake machines

- You can modify the hardware configuration on the CNC yourself

Click here to know other cnc press brake machine model cases:

- WEK 63 TONS 2500MM Hydraulic CNC Press Brake For Sale

- WEK 100 Tons 3200mm Hydraulic CNC Press Brake Machine For Sale

- WEK 400 Tons 6000mm Hydraulic CNC Press Brake Machine For Sale

- WDK 200 Tons 4000mm Hybrid Servo Press Brake Machine For Sale

- WDK 160 Tons 3200mm Hybrid Servo Press Brake Machine For Sale