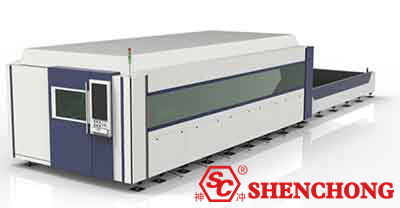

Model SC-D3015

Working Size 3000*1500mm

Stroke (X/ Y/ Z Axis) 3050mm/1550mm/280mm

Machine Size (L*W*H) 8610x2650x 2106mm

Machine weight (kg) 11500

Laser Source RAYCUS

Laser Power 6KW

Positioning Accuracy ±0.03mm

Repositioning Accuracy ±0.02mm

Max. Position Speed 120m/min

Max. Acceleration 1.2G

Working table exchange time 14s (adjustable)

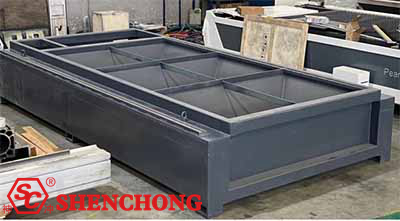

Machine cutting table: SHENCHONG

Laser power: Raycus

Laser head: BOCI BLT641

Chiller: Tongfei

CNC controller: Cypcut 2000S

Gear rack: YYC

Rail guide: Bosch Rexroth/INA

X/Y/Z axis servo: YASKAWA

Nesting software: CAD nesting

Planetary gearbox: Shimpo

Proportional valve: SMC

Transformer: SHENCHONG

Pressure valve: Parker

Auto height controller BCS 100E

Stabilizer: SHENCHONG

Relay: Schneider

Other valves: SMC

AC: Tongfei

Main body frame: The whole main body of the tool is made of the carbon structural steel with the staggered honeycomb welding structure, which is machined roughly after stress annealing and then the vibration aging treatment is performed. The natural aging may completely eliminate the welding and machining stress. With good rigidity and high precision, it may maintain normal use for 20 years without deformation.

Give up wire cable connection, easy to install and quick to put into production, minimizing your waiting time for working. Designed as high-standard sealing style to prevent dust from entering in and components from being ignited.

- INTEGRATED STEEL MOLD: Monolithic cast aluminum beam, light weight, high strength, no deformation. Molded and framed by integral steel mold and diecasting technology, light crossbeam make equipment a high operation speed, improving processing efficiency and processing quality.

- HIGH SPEED: The light crossbeam can ensure the machine have high moving speed and improve the processing efficiency.

- MORE EFFICIENT: The aluminum profile beam of the aerospace industry makes the equipment have efficient dynamic performance, greatly improving processing efficiency while ensuring processing quality.

The product has a built-in motor drive unit, and the linear mechanism drives the focusing mirror to automatically change the position within the range of 24mm. The user can set continuous focusing through the program, complete the fast perforation of thick plate and automatically cut the plate of different thickness and material.

BM series auto cutting | BM110 high-performance automatic focus cutting head

- Excellent design: Optimized optical configuration and smooth and efficient airflow design significantly improve cutting quality and efficiency.

- Auto focus: Automatic focusing, reduce human intervention, automatic focusing range -12~+10mm, focusing accuracy 0.05mm.

- Multiple protection lens: Collimation increase protection lens, effectively protect the collimation lens.

- Drawer type mirror holder: Quick and simple replacement of protective lens.

- High adaptation: With QBH, QD and other types of fiber interface, can be adapted to various mainstream lasers.

FSCUT2000C system is a high performance open loop laser control system. Widely used in metal, non-metal laser cutting field.

- Leapfrog: To be more efficient and faster in the plenty of cutting motion.

- Adaptive edge finding skip function: To detect the frame of the metal plate automatically.

- automation acceleration and deceleration of corners: System has automatic corner acceleration and deceleration function, combined with laser energy following mode, which can effectively prevent corner over- cutting and burning.

Laser power: 2 years warranty, Guaranteed by laser power manufacturer Shenchong Machine table: Ten years warranty, Guaranteed by Shenchong Electronics and motion parts: One year warranty, Guaranteed by parts manufacturer

Free Warranty Service: We will send replacement parts on our cost first, keep customer's machine running is top concern.

If machine needs onsite service for quality issue, we send technician to anywhere on our cost. You may inquire any of our old international customers for reference!

Product's real warranty relies on the original parts manufacturer, not the machine manufacturer. We can NOT offer warranty that we are unable to fulfil it. We don’t play for one-time business.

Many China factories offer cheap price and 2 or 3 years warranty, but during warranty period, you can really get free replacement and onsite service?

Or they tell you need to pay expensive international express, and stop your machine, wait long time for return damaged parts to repair and replacement?

Or they're busy; currently have no technician to your site for old machine service?

Cheaper price never goes together with better service. You will get what you paid for it always makes sense.