The plate bending rolling machine has developed from a 2 roll bending machine to a 3-roll bending machine and a four-roll bending machine. We mainly talk about the three-roller bending machine. Introduce from three aspects of three-roll bending machine type, working principle and characteristics.

3 roll plate rolling machine is a machine that can roll metal sheets into round, arc and conical work pieces within a certain range.

It has mechanical type and hydraulic type 3 roll plate bending machine.

And mechanical 3 roll plate bending machine is divided into symmetrical and asymmetrical type.

The upper roller of the plate bending machine is symmetrically located at the center of the two lower rollers, and it acts on the piston to move vertically through the hydraulic oil in the hydraulic cylinder.

The final gear of the main reducer drives the gears of the two lower rollers to mesh and rotate to provide torque for the rolled plate.

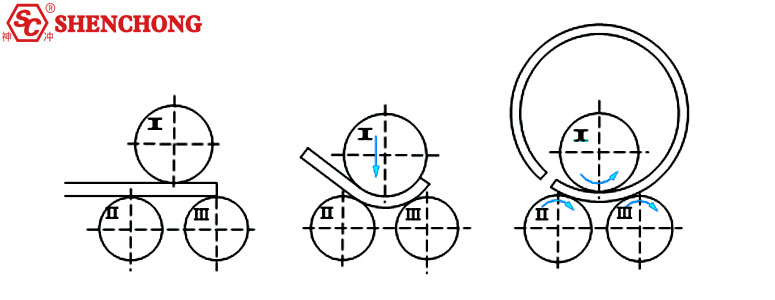

The plastic metal plate is placed between the three working rolls (two lower rolls and one upper roll) of the bending machine.

With the help of the downward pressure of the upper roll and the rotation of the lower roll, the metal plate is continuously bent through multiple passes, resulting in permanent Plastic deformation, rolled into the required cylinder, cone or other.

The upper roller of the three-roller symmetrical plate bending machine moves vertically at the center of the two lower rollers at a symmetrical position, which is obtained by the transmission of the screw nut and worm.

The two lower rollers rotate and are driven by a motor.

The output gear of the reducer meshes with the lower roller gear to provide torque for the rolled sheet.

The upper roller of the asymmetric three roll bending machine for sale is the main drive, the lower roller moves vertically, and meshes with the upper roller gear through the lower roller gear, as the main transmission.

The side rollers are tilted and lifted, with pre-bending and rounding Function. Compact structure, convenient operation and maintenance.

The upper roller of the hydraulic three-roller bending rolls can be vertically raised and lowered, and the vertical lifting hydraulic transmission is obtained by the hydraulic oil in the hydraulic cylinder acting on the piston rod.

The lower roller is driven to rotate, and there is a supporting roller under the lower roller, which can be adjusted.

Simple structure, light weight, easy manufacturing and maintenance, and low investment. The rollers on both sides can be made very close and the forming is more accurate, but the remaining straight edges are large.

The disadvantage of the 3 roll symmetrical plate rolling machine is that the end of the plate needs to be pre-bent with other equipment.

Applicable scope and conditions: equipped with pre-bending equipment or all kinds of bending work that do not require bending, use a symmetrical type.

Features: this machine can roll small diameter cylinders, and the end can be formed on this machine at one time

Advantages: compact structure, convenient operation and maintenance.

A.

The work is stable, the impact and vibration are small, and the noise is small, which has great benefits to the health of workers, the foundation of the plant, the surrounding environment and the equipment itself.

B.

Easy to adjust pressure and speed.

Using the hydraulic pressure of the working fluid to transfer energy can be made using the method of regulating the pressure limiting and regulating the various pressure control valve, and the overload can be reliably prevented, and help protect the die equipment.

Large adjustment range of the moving speed of the moving beam, can be adapted to different requirements of different processes operating speed.

C.

It is easy to get larger total pressure and larger working space. This is the most prominent advantage of hydraulic presses.

Based on the principle of hydraulic transmission, the actuator structure of the hydraulic machine is simple, and the power equipment can be arranged separately, and it can work in multiple cylinders. The hydraulic pressure and the working area of the piston (or plunger) can be changed in a large range.

And because the hydraulic press is a static pressure equipment, it does not need a large foundation, so it can achieve a large tonnage.

At present, hydraulic presses are mostly used in all types of forming equipment that require larger pressing tonnage, and hydraulic presses are almost all over 100,000 KN.

D.

The hydraulic plate rolling machine is more suitable for plates with a long width rolling. It is easy to get a large working stroke, which is convenient for pressing large-size work pieces, and can generate the rated maximum pressure at any position of the stroke, and can hold the pressure for a long time.

This feature of hydraulic press is very necessary for some processing techniques, such as deep drawing, extrusion, plastic molding, super-hard material synthesis, etc.

Click here to know: How To Bend Cone Workpiece With Plate Rolling Machine