SHENCHONG 2WEK 600 Ton 12000mm tandem light pole bending machine from China for sale with ESA S630 Controller and front feeding device.

(optional front feeding device)

To meet customers' large plate bending requests, SHENCHONG announce 2WEK heavy duty CNC light pole bending Machine, which has become the most popular heavy duty press brake type in the global market. 2WEK Serie tandem press brake is equipped with a touch-screen graphic programing CNC controller and is available in 4 axes in total with 2 axes back gauge. Tandem heavy duty CNC press brake also have front feeding device and side unloading device. 2WEK Serie is intended and designed for customers looking for the basics and ease of use.

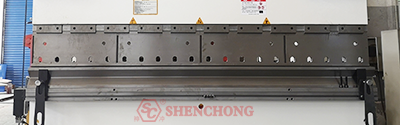

- The fuselage adopts integral welding and integral processing structure.

- Adopting the closed-loop control method composed of German electro-hydraulic servo valve and grating ruler, the slider position feedback accuracy is high, the operation is accurate and stable, the synchronization performance is good, and the bending accuracy is high.

- The CNC control system can realize the functions of bending angle graphic programming, angle correction compensation,automatic calculation and automatic adjustment of bending pressure, automatic calculation of the deformation compensation amount of the working table, the unfolded length of the work piece, and the automatic back gauge of the back gauge.

- ESA S630 controller controls the backgauge, which can continuous bend the complex workpiece

- 600 ton heavy duty press brake use punch adapter for large press brake upper punch

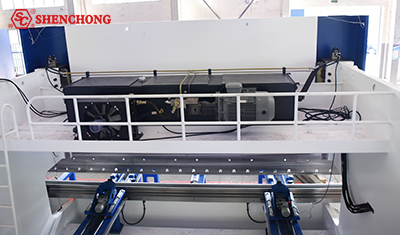

- 600T 12000mm 4 axis CNC light pole bending machine use different back machine structure. It has a stepladder at the machine back, which is easy for users to maintain the press brake.

- Or 2WEK 600 Tons 12000MM can use back gauge rear feeder.

- 600Ton 12000mm tandem press brake use heavy duty back gauge structure.

- 2WEK 600 Tons 12000mm tandem light pole bending machine can also operate seperately as two WEK 300 Tons 6000mm CNC press brake machine.

- Nominal Pressure: 600 Tons

- Length of Table: 12000mm

- Distance Between housings: 4800mm (per press brake)

- Throat Depth: 400mm (or we can customized based on your needs)

- Stroke: 250mm

- Open Height: 500mm

- Main Motor: 22x2 kw

- Approach speed: 100mm/s

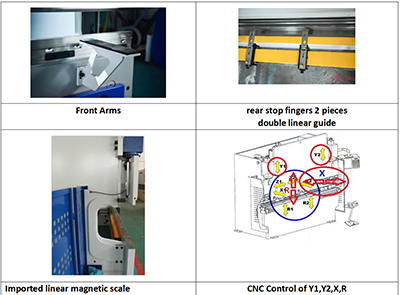

- Axis(4+V): Y1, Y2, X, R +V

- Y1,Y2 parallel tolerance: ±0.01mm

- X precision: ±0.015mm

- X movable distance: 5-1000mm

- Overall Dimensions: 6600x2250x3500mm (per press brake)

- Weight: 56 Tons

CNC axis description:

Y1, Y2 axis—controls the CNC axes of the cylinders on both sides. The X-axis controls the back gauge and forth of the back gauge, the R-axis controls the back gauge up and down, the Z1,Z2 axis control the back gauge finger left and right, and the V-axis table is CNC crowning.

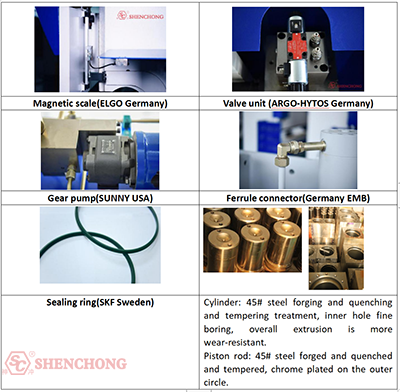

- Magnetic scale (ELGO Germany)

- Valve unit (ARGO-HYTOS Germany)

- Gear pump (FIRST USA)

- Ferrule connector (EMB Germany)

- Sealing ring (SKF Sweden)

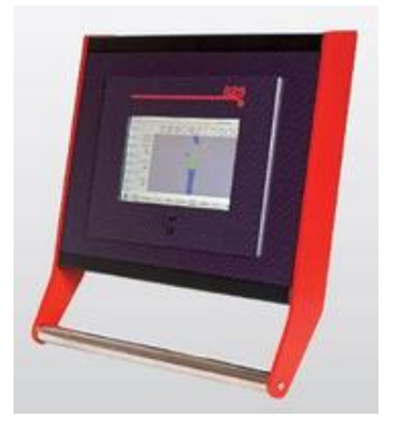

- ESA S630 CNC controller (Touch Screen from ESA Italy)

- Main motor (SIEMENS)

- V axis table crowning (CNC controlled)

- Backgauge servo motor (DELTA Taiwan)

- Electrical components (Schneider France)

- Movable foot pedal for esay operation and emergency power off function

- Shenchong CNC press brake standard safety protection includes:

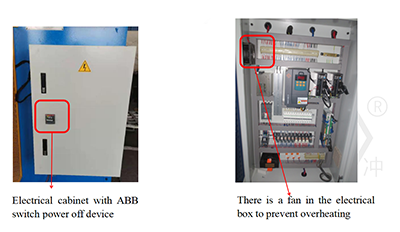

- Electrical cabinet with ABB switch power off device

- Fan in the electrical box prevent overheating

- Cooling device to prevent overheating of oil tank

- Graphic color 10” touch screen display (1024 x 600 pixels resolution).

- 128 silicon disk.

- Interactive 2d graphic editor for work-pieces and tools data entry.

- 2D graphic display of machine frame, work-piece and tools.

- Manual 2D graphic identification of the best bending sequence(option)

- 4 fast counting circuits for line drive 0-5Vdc differential encoders or npn/push pull. The encoders are powered at 5Vdc (max 200mA per channel).

- 4 analog outputs(±10V) with 13bits + sign resolution.

- 4 digital inputs for the zero micros.

- 4 analog inputs, 12 bits resolution, ranges 0÷10V, 0÷5V.

- 2 general purposes analog outputs, 0÷10V (8 bits resolution).

- 32 digital inputs (24Vdc).

- 32 digital outputs (24Vdc, 0,7A max.) protected against overload and short-circuits.

- 2 serial port rs232.

- 1 Can port with 9 pins subd f connector.

- 1 ethernet port 10/100 Mbit (lan connection)

- 1 VGA port for external monitor connection

- 2 USB (2.0) ports.

- 24Vdc power supply

We also provide other CNC controller option: DELEM, CYBLEC, ELGO... Welcome to contact with our sales for more machine details.

As a professional heavy duty press brake machine manufacturer, Shenchong always focus on customers' satisfaction.

We will arrange for engineers and installers to go to the site for installation, commissioning and training, which is about 3 days. Or you can arrange for people to come and study.

The warranty period of the machine is 13 months, including one month in shipping.

If there is any problem, we will first check the machine problem through video and guide the repair. If it still cannot be solved, an employee will be sent to the site for repair.

During the warranty period, non-human damage, parts damage shall be responsible by the seller.